🖥️ 1960s–1970s: The Birth of Computerized Maintenance

CMMS originated during the early adoption of computers in the 1960s. Industries such as manufacturing, oil & gas, and utilities used mainframe computers to manage maintenance records and schedules. These systems were basic, focusing mainly on data storage and simple reporting.

💾 1980s: The Rise of Dedicated CMMS Software

With the arrival of personal computers, CMMS became more accessible. Dedicated maintenance applications replaced paper-based systems, allowing organizations to automate work orders and asset tracking on individual machines.

🖧 1990s: Networked & On-Premise CMMS

Client-server architectures enabled shared databases and improved collaboration. CMMS systems were installed on local servers and required significant IT infrastructure, becoming the industry standard.

🌐 2000s: The Internet Era

The rise of the internet enabled web-based CMMS solutions. Organizations began accessing maintenance data through browsers, marking the early transition toward Software-as-a-Service (SaaS).

☁️ 2010s: The Cloud Revolution

Cloud-based CMMS transformed maintenance management by offering scalability, mobile access, lower costs, and automatic updates. Hardware dependency disappeared, enabling faster adoption for organizations of all sizes.

🚀 Today: Intelligent & Connected CMMS

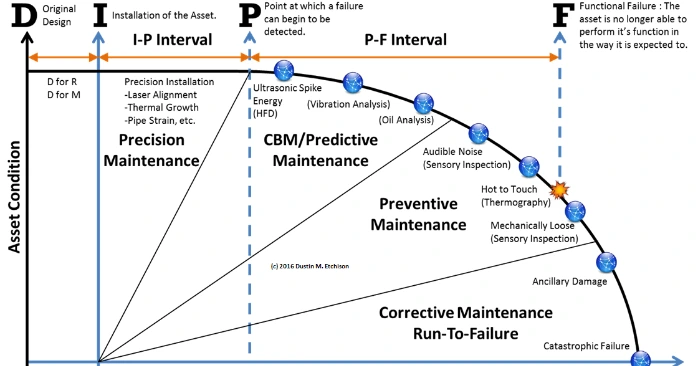

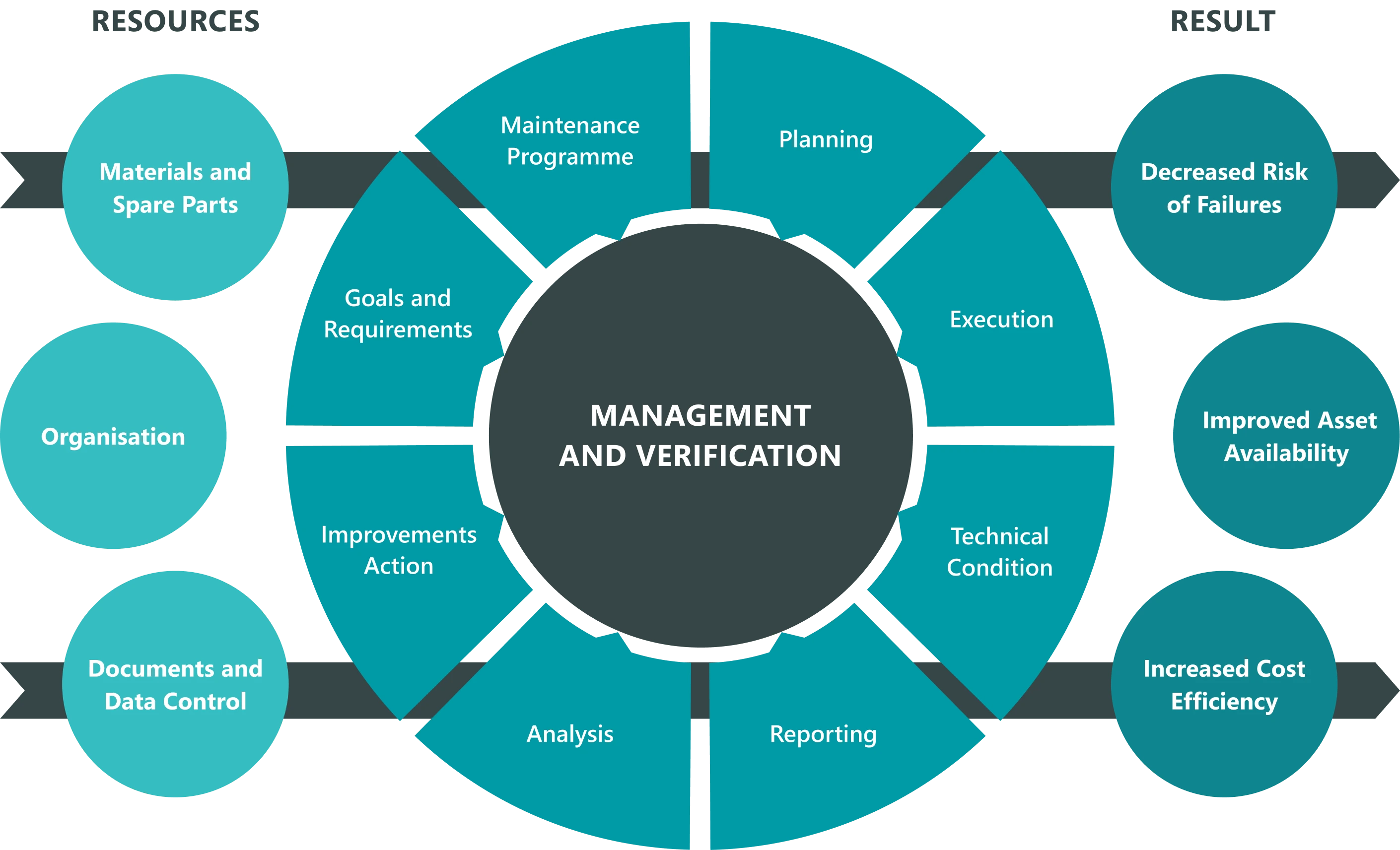

Modern CMMS platforms integrate mobile apps, IoT sensors, predictive maintenance, and analytics—making them essential tools for data-driven, proactive maintenance strategies.