IntelliMaintPreventive Maintenance

Streamline Preventive Maintenance with Smart Scheduling

Easily schedule preventive maintenance

Assign Team

Track tasks and repeated intervals

Easily schedule preventive maintenance tasks on any cadence—daily, weekly, monthly, yearly, or custom intervals. Never miss critical maintenance again. Reduce Downtime, Boost Reliability Proactive maintenance planning cuts unexpected breakdowns by up to 45%. → Try IntelliMaint’s PM Features Today.

Reduce maintenance costs and maximize uptime with runtime-based Preventive Maintenance

With IntelliMaint’s Meters feature, you can automate preventive maintenance based on machine cycles, mileage, run-time hours, or any custom unit of measure. Build a flexible maintenance program triggered by real usage—not just time. According to the U.S. Department of Energy, investing in preventive maintenance can save organizations an average of 10% to 20% in costs.

Boost Technician Productivity

No more scribbling notes on paper and retyping them later. Everything is organized, accessible, and always up to date. The result? Faster workflows and fewer errors.

To ensure asset last Service precision

Defines Meter Reading for machine or asset

- Hours

- Km

- Mile

- Days

How do you prefer to repeat this tasks.

Specifies the category of service Type

- Repeat

- One Time task

Provides clarity on what needs to be done and keeps everyone updated on progress, improving workflow and reducing miscommunication.

Task Schedule to do in:

- Hours

- Day

- Week

- Month

- Year

When do you want to nitified for tasks.

Notify me before this:

- Hour

- Day

- Week

- Month

One manufacturing company even reported a 90% reduction in time spent on paperwork. With a CMMS solution, technicians can eliminate the time-consuming, burdensome task of double data entry. They no longer need to record information related to work orders on paper, then spend time entering that data into desktop software once the work order is complete. Instead, they can use their mobile-friendly app to log data onsite in real-time; which boosts their efficiency and productivity. Plus, a CMMS organizes work orders so technicians always have access to the right information in a single, up-to-date place. See how one manufacturing company’s technicians saw a 90% reduction in time spent filling out paperwork!.

Get in touch today!CMMS Software Features and Solutions

As you evaluate your options for CMMS software implementation, make sure the tool you choose offers these essential features.

Preventive Maintenance

Mobile Maintenance Made Simple

Service Work order

How can we enhance your maintenance operations?

Our advanced work order management ensures every maintenance task is executed with precision, efficiency, and complete transparency. We focus on clear task definitions, smart prioritization, and accurate resource allocation to keep your operations running smoothly. From preventive maintenance to urgent breakdown repairs, our system delivers seamless coordination between teams, real-time status tracking, and complete documentation of labor, parts, and materials. Collaborate with us to streamline your workflow, reduce equipment downtime, and gain full control over your maintenance activities. Share your maintenance goals, and let’s build a smarter, more efficient work order process together.

How can we improve your inspection process?

Our inspection management tools ensure every check is carried out thoroughly, consistently, and on schedule. We focus on clear inspection criteria, accurate data collection, and real-time reporting to maintain safety, compliance, and equipment reliability. From routine inspections to critical safety checks,our system enables seamless coordination, digital documentation, photo evidence capture, and instant follow-up actions when issues are found. Partner with us to streamline your inspection workflows, reduce risks, and maintain the highest operational standards. Share your inspection requirements, and let’s elevate your safety and compliance process together.

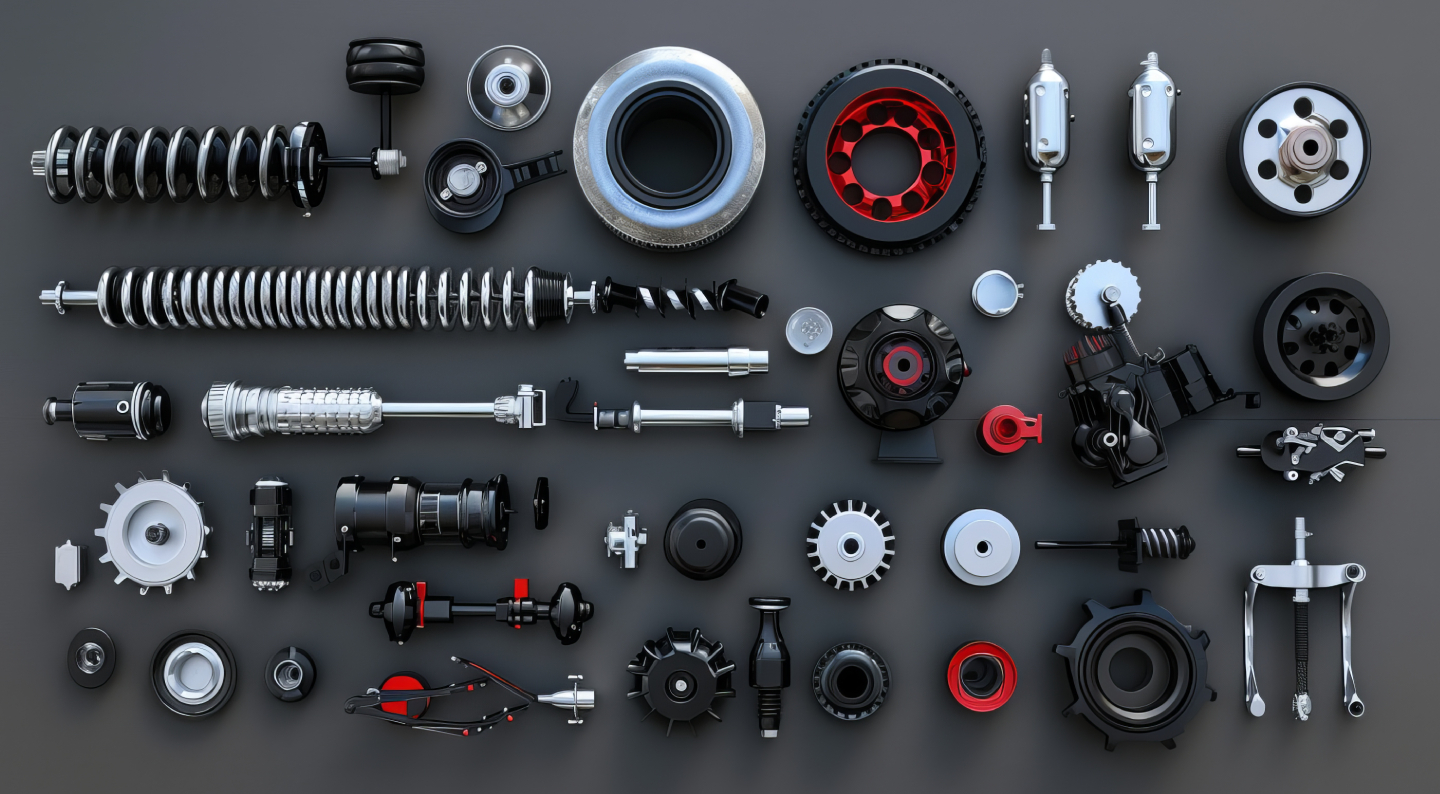

How can we optimize your spare parts management?

Our spare parts management system ensures your inventory is always accurate, accessible, and ready to support your maintenance operations. We focus on real-time stock tracking, smart reordering, and detailed part histories to prevent shortages and minimize downtime. From critical components to consumables,our tools provide clear visibility into quantities, locations, suppliers, and usage trends—all in one place. Collaborate with us to streamline your inventory workflow, reduce unnecessary costs, and ensure every maintenance task has the parts it needs. Share your inventory challenges, and let’s build a more efficient and reliable spare parts management process together.

How can we simplify your purchase order process?

Our purchase order management system ensures every procurement request is handled with accuracy, transparency, and complete control. We streamline vendor selection, order approvals, and cost tracking to help you secure the right parts and materials at the right time. From generating purchase orders to monitoring delivery status, our tools provide clear documentation, prevent errors, and support seamless communication with suppliers. Partner with us to optimize your procurement workflow, reduce delays, and keep your maintenance operations fully supplied. Share your purchasing needs, and let’s create a smarter, more efficient purchase order process together.

RESERVATION

Book a Demo

Business Industries

Providing solutions for this sectors

Contact

Contact Us

Location

Industrial Area zone-1, October City, Giza

Open Hours

Monday-Saturday:

8:00 AM - 1700 PM

Call Us

+20 1222573811