What is a CMMS?

A computerized maintenance management system (CMMS) is a maintenance management software that consolidates data and activities for streamlined asset management.

The History of CMMS?

The 1960s and 1970s: The Emergence of Computerized Maintenance The concept of CMMS originated during the early adoption of computers in the 1960s. Industries such as manufacturing, oil and gas, and utilities began using mainframe computers to manage maintenance records and schedules. These early systems were rudimentary and mainly used for storing data and generating simple reports. The 1980s: The Rise of Dedicated CMMS With the advent of personal computers in the 1980s, CMMS became more accessible. Software developers began creating dedicated applications for maintenance management. These systems were installed on individual computers, allowing organizations to move from paper-based systems to more automated processes. The 1990s: Networked and On-Premise CMMS In the 1990s, client-server architectures enabled networked CMMS solutions. Maintenance teams could now access shared databases, which significantly improved collaboration. On-premise CMMS systems became the standard, and they were installed on local servers and required significant IT infrastructure and support. The 2000s: The Move to the Internet The rise of the Internet in the late 1990s and early 2000s paved the way for internet software. Organizations began to explore web-based solutions, where data is hosted remotely and accessed through web browsers. The end of the decade marked the beginning of the shift toward Software-as-a-Service (SaaS) models. The 2010s: The Cloud Revolution In the 2010s, CMMS software moved to the cloud, transforming maintenance management by offering unprecedented accessibility, scalability, and cost-efficiency. Cloud-based CMMS enables users to access maintenance data anywhere via web browsers or mobile devices. Cloud hosting eliminated the need for costly hardware and IT infrastructure, shifting to a subscription-based model with automatic updates. It improved data security and backup reliability while simplifying implementation and scaling for organizations of all sizes. The Present: Web-Based CMMS as the Norm Today, web-based CMMS solutions dominate the market. These platforms offer advanced features such as mobile compatibility, predictive maintenance tools, and integration with Internet of Things (IoT) devices, making them indispensable for modern businesses.

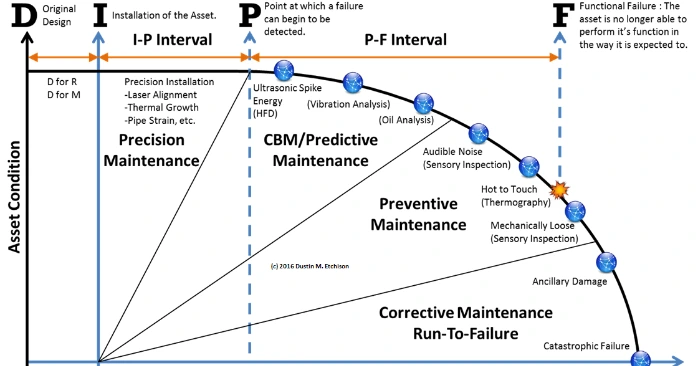

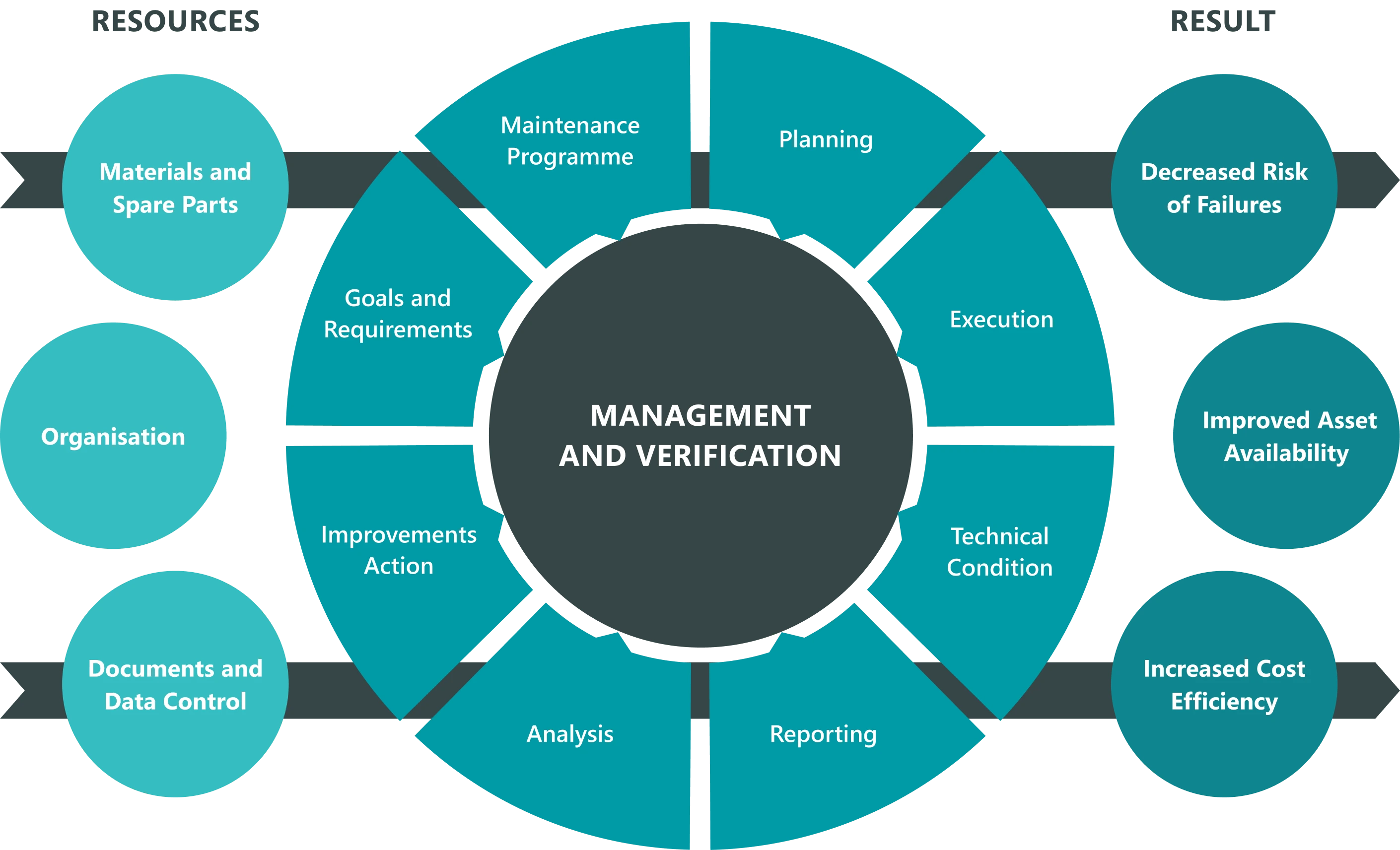

Maintenance strategies

Maintenance strategies are an essential facet of operational performance in any asset-reliant industry. The right maintenance approach can reduce downtime, save costs, and extend the life of equipment. However, choosing the appropriate strategy is often a complex task that requires a deep understanding of various methodologies and their impacts. In this blog, we explore the different types of maintenance strategies and provide insights on selecting the most suitable one for your business needs. Understanding the Spectrum of Maintenance Strategies Before diving into selection criteria, it's crucial to understand the different maintenance strategies available. Reactive Maintenance (Breakdown Maintenance) Reactive Maintenance occurs when repairs are made after a piece of equipment has failed or when its performance has degraded significantly enough to impact operations. This approach does not involve preventative measures or scheduled checks but rather a response-based action triggered by equipment malfunction or breakdown. Preventive Maintenance (Scheduled Maintenance) Preventive Maintenance involves scheduled maintenance tasks that are performed on equipment at predetermined intervals to ensure it continues to operate efficiently and to minimize the possibility of unplanned downtime due to equipment failure. These tasks are typically outlined based on time intervals (e.g., monthly, quarterly) or usage milestones (e.g., every 1,000 hours of operation). Predictive Maintenance (Condition-Based Maintenance) Predictive Maintenance (PdM) utilizes various diagnostic tools and techniques, such as vibration analysis, thermal imaging, and acoustic inspections, to monitor the condition and performance of equipment during its normal operation. By continuously collecting and analyzing data from equipment sensors, this strategy allows maintenance teams to identify potential issues before they lead to failure. Reliability-Centered Maintenance (RCM) RCM is an advanced maintenance strategy that revolves around the reliability of system components and prioritizes maintenance actions based on the risk and consequences of failure. This maintenance philosophy was originally developed for the aviation industry but has since been adopted widely across various sectors that require high reliability, such as manufacturing, energy, and transportation. Total Productive Maintenance (TPM) TPM is a maintenance philosophy developed in Japan in the 1970s, derived from the preventive maintenance strategies of the United States. It emphasizes proactive and preventive maintenance to maximize the operational efficiency of equipment. TPM aims to empower all employees to take part in maintenance activities through continuous improvement and problem-solving efforts based on teamwork. Choosing the Right Maintenance Strategy Selection of a maintenance strategy depends on several factors: Assessing Equipment Criticality: Determine how crucial each piece of equipment is to your operations. High-criticality assets might require more robust strategies like RCM or predictive maintenance. Understanding Asset Lifecycle: Analyze where each asset is in its lifecycle. Older equipment might benefit more from preventive maintenance, while newer technology can be monitored effectively with predictive approaches. Calculating Cost Implications: Consider both direct costs (such as repairs) and indirect costs (such as downtime). Predictive and RCM strategies may require higher upfront investment but can offer savings over time. Evaluating Technical Capabilities: Do you have the technical resources to implement sophisticated strategies like predictive maintenance, or would a preventive approach be more realistic? Compliance and Safety Requirements: For certain industries, regulations may dictate maintenance strategies to ensure safety and compliance. Training and Culture: TPM requires a cultural shift and training at all levels. Assess if your organization is ready for such an approach. Implementing Your Chosen Maintenance Strategy Once you select a strategy, implementation involves: Creating a Detailed Plan: Outline all tasks, schedules, and responsibilities. Investing in Training: Ensure all relevant personnel are trained for the new maintenance regime. Monitoring and Adjusting: Use KPIs to track the effectiveness of your maintenance strategy and be prepared to adjust as necessary. Conclusion There is no one-size-fits-all approach to maintenance. The right strategy for your organization will align with your operational needs, asset criticality, and organizational capabilities. By carefully evaluating your unique circumstances and making informed decisions, you can choose a maintenance strategy that enhances reliability, efficiency, and profitability. If you're ready to develop a tailored maintenance strategy that aligns with your business goals and maximizes asset uptime, click the button below to get in touch with our experts today....

What Do Maintenance Managers Do? Roles, Responsibilities

Maintenance Managers

1.What is the primary role of a Maintenance

Manager?

The primary role of a Maintenance Manager is to

ensure the smooth and efficient operation of

equipment, facilities, and infrastructure within an

organization. This involves overseeing maintenance

activities, managing resources, and optimizing

maintenance strategies.

2.What are the key responsibilities of a

Maintenance Manager?

Key responsibilities include developing and

implementing maintenance plans, managing maintenance

budgets, supervising maintenance teams, ensuring

regulatory compliance, and continuously improving

maintenance processes.

3.What technical skills are essential for a

Maintenance Manager?

Technical skills like knowledge of mechanical,

electrical, and plumbing systems, as well as

familiarity with relevant software and tools, are

crucial.

4.What soft skills are important for a

Maintenance Manager?

Soft skills like leadership, communication,

problem-solving, decision-making, and the ability to

work effectively with diverse teams are highly

valuable.

5.How does a Maintenance Manager contribute to

an organization's bottom line?

By minimizing downtime, preventing equipment

failures, optimizing maintenance costs, and

extending the lifespan of assets, Maintenance

Managers directly impact a company's profitability.

6.What are the challenges faced by Maintenance

Managers in today's environment?

Challenges include managing aging infrastructure,

adapting to rapidly changing technologies,

attracting and retaining skilled technicians, and

ensuring compliance with increasingly stringent

regulations.

7.How does a Maintenance Manager ensure

workplace safety?

Maintenance Managers establish and enforce safety

protocols, conduct regular inspections, provide

safety training to employees, and promptly address

any safety concerns.

8.How can a Maintenance Manager improve the

efficiency of maintenance operations?

By implementing preventive and predictive

maintenance strategies, utilizing data analytics to

identify patterns and trends, and embracing

automation and smart technologies.

9.What is the career path for a Maintenance

Manager?

Maintenance Managers often start as technicians and

progress to supervisory roles before becoming

managers. With experience, they can move into senior

management positions or specialize in specific

industries.

10.What certifications or qualifications are

beneficial for a Maintenance Manager?

Certifications like Certified Maintenance and

Reliability Professional (CMRP) or Certified

Reliability Leader (CRL) can enhance a Maintenance

Manager's credentials and demonstrate their

expertise.

CMMS Software Features and Solutions

As you evaluate your options for CMMS software implementation, make sure the tool you choose offers these essential features.

Streamlined Work Order Management

Modern CMMS software like IntelliMaint centralizes the creation, prioritization, and tracking of maintenance work orders. With intuitive tools, teams can easily attach photos, documents, and videos—ensuring clarity, accountability, and faster completion. Boost productivity and maintain accuracy with every task, all from one smart platform.

Smarter Inventory Management

Take control of your inventory with a powerful system that simplifies every step of the process. IntelliMaint gives you real-time visibility into stock levels, part usage, purchasing, and pricing—so you can reduce waste, cut costs, and keep your operation running without delays.

Preventive Maintenance

Boost productivity and reduce unplanned downtime with IntelliMaint’s intuitive preventive maintenance tools. Easily schedule recurring maintenance, set smart alerts for parts availability, and gain full visibility into costs—all in one centralized platform. Stay ahead of issues and extend the life of your equipment with minimal effort.

Mobile Maintenance Made Simple

Stay connected and in control—anytime, anywhere. IntelliMaint’s mobile-first CMMS empowers your team to track, manage, and complete maintenance tasks on the go. Whether on the shop floor or in the field, users have real-time access to work orders, asset history, and inventory—right from their mobile device.

Industries That Utilize CMMS

Organizations across various industries are now leveraging CMMS software, including:

Our work Gools

Our solutions will make life easier for our customers.

1

Save Assets

2

Reduce Breakdown

3

Customer Satisfaction

“ IntelliMaint makes it easy to stay on top of work orders and supplies. Everyone knows what’s going on, and each team member is responsible for their tasks. Simplifies work order and supply management by enabling real-time tracking and updates across users. Task accountability is built in for every team member.”

“IntelliMaint is intuitive and efficient. It supports our shift to a paperless workflow, simplifies work order creation, and ensures maintenance tasks are never missed with timely scheduling reminders.”

“IntelliMaint makes everything easy and organized in one place. I also appreciate that our Operations Manager can see everything I’m working on.”

“Service has been awesome. if you have a fleet of asset you can control every asspect.”

Get Connected with all your staff and maintenance teamsjust in real time.

Report, track and coordinate repairs. Good for asset, equipment & asset repair management.

IntelliMaint is available to download at Google Play Store.